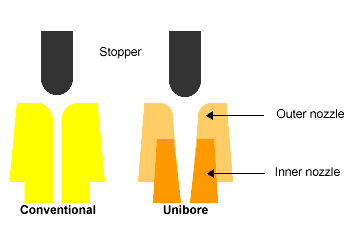

Capital Refractories’ licensed and patented Unibore system, already proven in bottom pour ladles, has been further developed for use with Autopour systems. This unique system utilises a two part nozzle; an outer part which is re-useable and an inner part which offers a wide range of bore sizes. The outer nozzle remains as part of the refractory lining and is changed around once a week. The inner nozzle can be replaced with ease daily and enables the user to alter the bore size for each casting accordingly. The tapered nozzles are far less likely to block than the conventional parallel nozzle. The Unibore system enables a more stable and controllable metal flow and allows for a quicker turn-around of the pouring system. It is complemented by Multicast – Capital Refractories’ reusable stopper system.

Unibore with Autopour has been specifically designed to accommodate a shallow nozzle which caters for the small gap between the autopour tundish and mould.

The advantages of using Unibore with Autopour include:

1、Downtime is reduced. The Unibore inner nozzle can be removed and changed allowing casting to be re-started quickly.

2、Labour is reduced due to the reduced changeover time.

3、The amount of metal poured can be accurately controlled.

4、A higher casting quality.

5、Reduction in waste – greater control reduces spillage.

6、Unibore with Autopour helps to keep pace with high speed mould machines.

7、The system allows for consistent pouring.